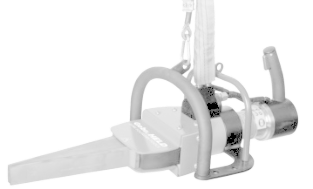

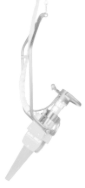

standard wedg

e

multi-

rotatable wedge

suspension point 1

suspension point 2

FEATURES

FOUNDRY

WEDGES

Quick and ea

sy to use

The

wedge

blades

of

the

Gebr.

HELD

foundry

wedge

are

durable

and

can

be

replaced

very

quick-ly.

No

tools

are

needed,

only

a

few

simple

operations

are

suf

昀椀

cient

to

replace

the

b

lades

within

30

seconds!

The

pump

unit

can

be

activated

by

means

of

a

push

button

on

top

of

the

tools

user-friendly

handle.

A

high

number

of

spreading

cycles

per

minute

ensures

a

high

operation

speed.

Safe to ope

rate

Gebr.

HELD

found

ry

wedges

are

outstanding

in

the

safety

of

their

oper

ation.

Attributes

such

as

a

full

protection

cover

and

the

fact

that

the

tools

suppor

ts

two-handed

operation,

greatly

limit

the

chances

of

accidents

happening.

Another

feature

is

that

the

tool

provides

clean

predictable cuts, guaranteeing that feeders and risers break in a controlled manner.

Erg

onomics

During

the

design

stag

e

of

the

HFW

foundry

wed

ge,

our

engineers

emphasised

the

tool’s

ergo-nomic

aspects.

The

result:

wedges

implicating

that

the

op

erator

can

reach

almost

any

feeder

and

riser

without

repositioning

the

casting.

The

unique

construction

of

the

multi-rotatable

wedge

goes

even

further

and

is

very

suitable

for

the

positioning

in

any

required

direction,

including

ver-tically.

Both

types

avoid

unnecessary

heavy

handling.

Because

the

physical

burden

signi

昀椀

cantly

reduces

a

more

ef

昀椀

cient

pr

oduction

process

will be the result.

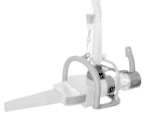

Positioning

The standard wedge has two stand

ard suspension points:

Suspension point 1 positions the tool horizontally

Suspension point 2 can be used for

angular positions

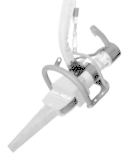

The

multi-rotatable

wedge

has

an

unique

suspension

construction

that

enables

the

wedge

to

be positioned in any required

direction, including vertically.

Standard supplied

with

Anti-friction coating Bel Ra

y

(400 ml)

Hand nut, T-grip (2 pieces)

Service instructions (plasticized)

Available on request:

Top handle (HFW 926)

Central

wedge

and

wedge

blades

manufactu-red in conformity with

customer speci昀椀cations